In the realm of industry, having control is non-negotiable. It’s the secret to ensuring safety, streamlining efficiency, and ramping up productivity. And how do we achieve control when managing the flow of fluids and gases? The answer is valve automation. This process uses an actuator, a device designed to adjust the opening and closing of valves, to regulate the flow. It’s a vital cog in the machinery of any industrial control system and offers significant advantages over traditional manual valve control.

Dive into this all-inclusive guide where we’ll unravel the nitty-gritty of valve automation – its workings, the benefits it brings to the table, and the top-notch actuator solutions like the AUMA actuator that promise efficient and reliable industrial control.

How Valve Automation Works

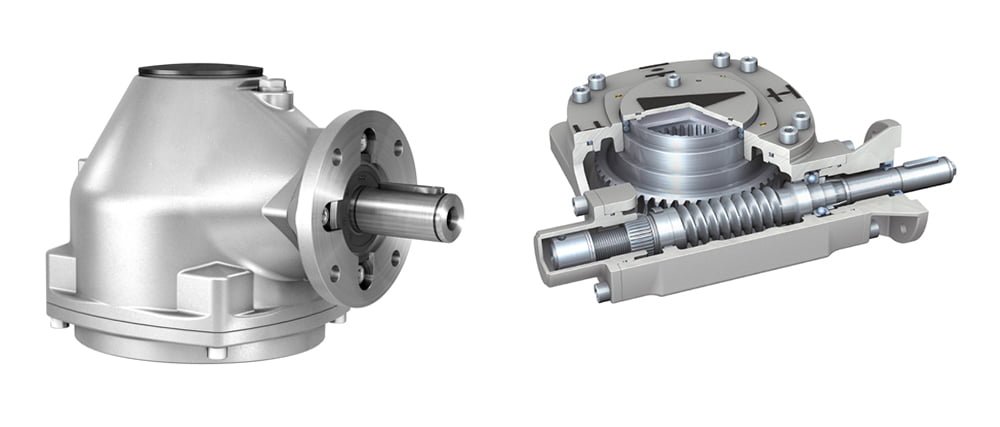

The main idea behind valve automation is employing an actuator—a device that changes energy into movement—to handle the opening and closing of valves. The actuator, which is hitched to the valve stem, does the job of valve operation. Depending on the needs of a specific situation, the actuator can be manipulated manually or can function automatically.

Within an automated setup, the actuator is tied to a control system. This system takes charge of when and how the valve opens and closes. The nifty part? This control system can be programmed to direct the valve based on a variety of factors. These could range from pressure and temperature to the rate of flow. It’s this adaptability that makes automated valve systems such a valuable tool in industrial settings.

Benefits of Valve Automation

Valve automation offers numerous benefits over traditional manual valve control. Some of the key benefits include:

Increased safety: Valve automation eliminates the need for manual valve control, reducing the risk of accidents and injuries.

Improved efficiency: Automated valves can be controlled more precisely and quickly, reducing the time required to adjust the valve and improving overall system efficiency.

Enhanced control: Automated valves can be controlled based on various parameters, allowing for greater control over the flow of fluids and gases.

Reduced downtime: Automated valves are less prone to failure and require less maintenance, reducing downtime and improving system reliability.

Actuator Solutions for Valve Automation

With a range of actuators up for grabs for valve automation, making a choice can be tough. Yet, thanks to its benefits, the AUMA actuator often comes out on top and is a popular choice for many.

For starters, the AUMA actuator screams quality. Here are some perks it brings to the table:

- Unmatched Performance: Designed for heavy-duty applications, the AUMA actuator doesn’t shy away from extreme conditions. It’s all set to deliver top-notch performance come rain or shine.

- Precision Personified: The AUMA actuator offers laser-like accuracy when controlling the valve position. It ensures you have control down to the last detail.

- Seamless Integration: The AUMA actuator is no fuss. It plays well with other control systems, ensuring installation and operation are as smooth as butter.

- Remote Control: Want to control your actuator from afar? No problem. The AUMA actuator offers remote control capabilities, giving you the flexibility and convenience to operate from a distance.

- Low Maintenance: The AUMA actuator doesn’t need constant pampering. Its low-maintenance design means you spend less on upkeep, effectively reducing the total cost of ownership.

FAQs

Q: What types of valves can be automated?

A: Almost any type of valve can be automated, including ball valves, gate valves, globe valves, and butterfly valves.

Q: What factors should be considered when choosing an actuator?

A: When choosing an actuator, factors such as the valve size, weight, and operating conditions should be considered.

Q: Can automated valves be controlled remotely?

A: Yes, many automated valves can be controlled remotely using a control system.

Conclusion for Valve Automation

Valve automation represents the cutting-edge frontier of industrial control, providing a wealth of advantages over traditional manual valve control. This innovative approach not only elevates safety measures but also boosts efficiency and grants superior control. When it comes to selecting the ideal actuator for valve automation, the AUMA actuator emerges as an outstanding choice, thanks to its exceptional performance, precise control, and seamless integration capabilities. Embracing valve automation alongside the AUMA actuator streamlines industrial control processes, ushering in unparalleled ease and efficiency. The future of industrial control has arrived, offering a world of possibilities for enhanced operations and optimized performance.