Actuator maintenance is a critical aspect of ensuring the optimal performance and lifespan of valves used in various industries. Actuators are essential components of valve automation systems that control the flow of fluids or gases by opening and closing the valve. In this blog post, we will explore the importance of valve actuator maintenance, provide tips on how to maintain them effectively and explain the importance of preventative maintenance of actuators.

Why is Valve Actuator Maintenance Important?

Preventing Downtime

Valve actuators can malfunction or fail due to a variety of factors, such as wear and tear, electrical faults, or mechanical problems. A faulty valve actuator can cause the valve to malfunction, leading to production downtime and lost revenue. Regular maintenance of valve actuators can help identify potential problems before they lead to costly downtime.

Ensuring Safety

Valve actuators are often used in critical applications, such as controlling the flow of hazardous chemicals or gases. A malfunctioning valve actuator can compromise worker safety and the environment. Proper maintenance of valve actuators ensures that they function optimally, reducing the risk of safety hazards.

Extending Equipment Life

Valve actuators are expensive components of valves, and their failure can lead to costly repairs or replacements. Regular maintenance of valve actuators can extend their lifespan and reduce the need for costly repairs or replacements.

Tips for Actuator Maintenance

Regular Inspection

Regular inspection of valve actuators can help identify potential problems before they escalate into major issues. Inspect for signs of wear and tear, leaks, corrosion, and other signs of damage. Check the electrical connections, wiring, and control systems for signs of wear or damage. Inspect the valve position indicator to ensure that it is correctly indicating the position of the valve.

Lubrication

Proper lubrication of valve actuators is critical to their functionality and longevity. Use the manufacturer’s recommended lubricants and follow the recommended lubrication schedule. Over-lubrication can lead to grease buildup, interfering with the actuator’s operation. Under-lubrication can lead to premature wear and tear of components.

Cleaning

Valve actuators can accumulate dirt, dust, and other debris over time, affecting their operation. Clean the valve actuator regularly using a soft brush or a damp cloth. Avoid using harsh chemicals or abrasive cleaners that can damage the actuator’s finish.

Calibration

Valve actuators require periodic calibration to ensure that they operate within the specified tolerances. Calibration involves adjusting the valve actuator’s settings to ensure that it opens and closes the valve accurately. Failure to calibrate the valve actuator can lead to inaccurate valve position, which can affect the system’s performance.

Replacement of Worn Components

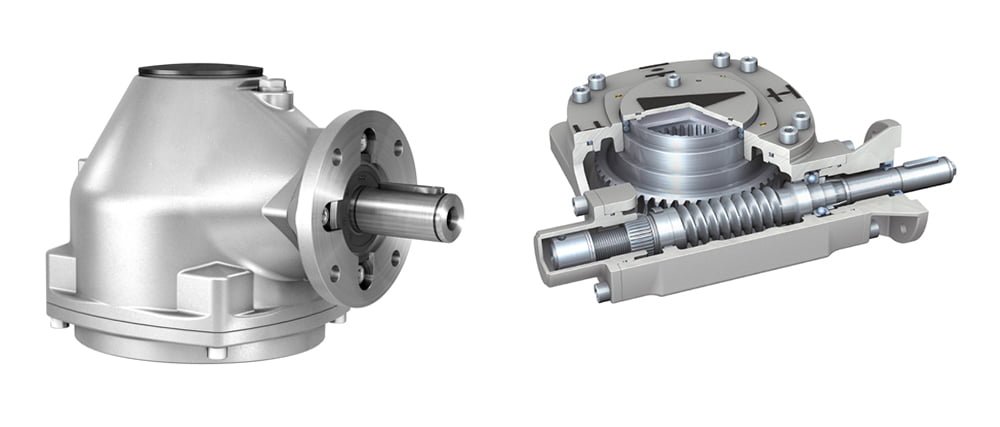

Valve actuators contain several components that wear out over time, such as bearings, seals, and gears. Replace these components when they show signs of wear to avoid costly repairs or replacement. Follow the manufacturer’s recommended replacement schedule for these components.

Training and Documentation on Actuator Maintenance

Ensure that all operators and maintenance personnel are properly trained on valve actuator maintenance procedures. Maintain accurate documentation of all maintenance activities, including inspections, lubrication, calibration, and component replacements.

Guideline for Preventative Maintenance of Actuators

Preventative maintenance is essential for all industrial plant equipment, including actuators, due to exposure to harsh conditions and the risk of damage from unforeseen events. Regardless of the quality of the equipment, it is crucial to implement a preventative maintenance program to ensure maximum operability, extend the lifespan of the equipment and reduce long-term costs. Regular health checks and maintenance programs are critical to keeping industrial equipment in optimal condition.

Benefits of Preventative Maintenance for Actuators

Implementing preventative maintenance for actuators offers several advantages.

- Preventative actuator maintenance can increase the reliability of actuators during use, identify potential problems before they cause damage or affect operability, and ultimately reduce overall maintenance costs.

- Regular maintenance also allows for small repairs to be made, which can prevent major shutdowns and schedule larger repairs at convenient times.

- By controlling and predicting costs, realistic budgeting becomes possible.

- According to Rotork, a market leader in Actuation, these guidelines should be followed in any preventative maintenance program.

Preventative Actuator Maintenance Guideline

The following guideline should be followed in any preventative maintenance program of a Rotork valve actuator.

- Inspect all external surfaces of the actuator, including paint finishes, control knobs, and valve stems.

- Check the oil level and refill as necessary.

- Inspect all mounting bolts, nuts, washers, and screws for damage and ensure they are tightly fastened.

- Verify that the handwheel is functioning properly and that there is a physical movement of the valve.

- Confirm that the local control works in both directions and check for any signs of deterioration, such as undue motor noise.

- Analyze historical performance data and compare it to optimum torque profiles.

- Remove the terminal cover and ensure all connections are tightly fastened. Check the compartment for any water ingress, and replace the o-ring seal. If the actuator is ex-proof, check the integrity of the flame path.

- Remove the motor cover and inspect the motor, checking the case for any signs of moisture ingress. Replace the ‘O’ ring. If the actuator is explosion-proof, inspect the integrity of the flame path.

- Remove the electrical cover and inspect the compartment, checking for any moisture ingress and the status of switches, contactors, and electrical apparel.

- Replace the ‘O’ ring. If the actuator is ex-proof, check the integrity of the flame path.

- Replace all cover screws, and apply grease to enable future removal and protect them from corrosion.

- Finally, check both the local and remote operation of the actuator.

Conclusion On Actuator Maintenance

Actuator maintenance is a critical aspect of ensuring the optimal performance and lifespan of valves used in various industries. Regular maintenance of actuators can prevent costly downtime, ensure worker safety, and extend the equipment’s lifespan. Follow the tips outlined in this blog post to maintain your valve actuators effectively. Proper maintenance of valve actuators will save you time and money in the long run and ensure that your valves operate efficiently and safely.