Water management is a critical aspect of our daily lives, and with the increasing demand for clean water, the use of advanced technology has become necessary. Valve actuators play a significant role in water/wastewater management systems by controlling water flow and ensuring it is distributed efficiently. These devices come in different types and sizes and can be used in various water management applications such as irrigation, wastewater treatment, and water distribution systems.

In this comprehensive guide, we will explore the power of actuators in water management and how they help optimize water resource use. We will also delve into the different types of actuators and their functions, the benefits of using actuators in water management systems, and the key factors to consider when choosing the right actuators for your specific water management needs. Join us as we uncover the power of actuators in water management and how they transform how we manage our precious water resources.

What are actuators, and how do they work?

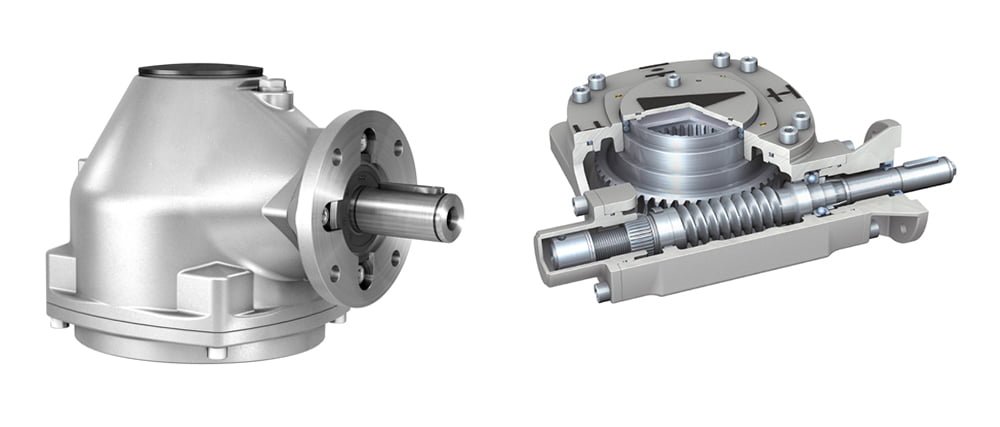

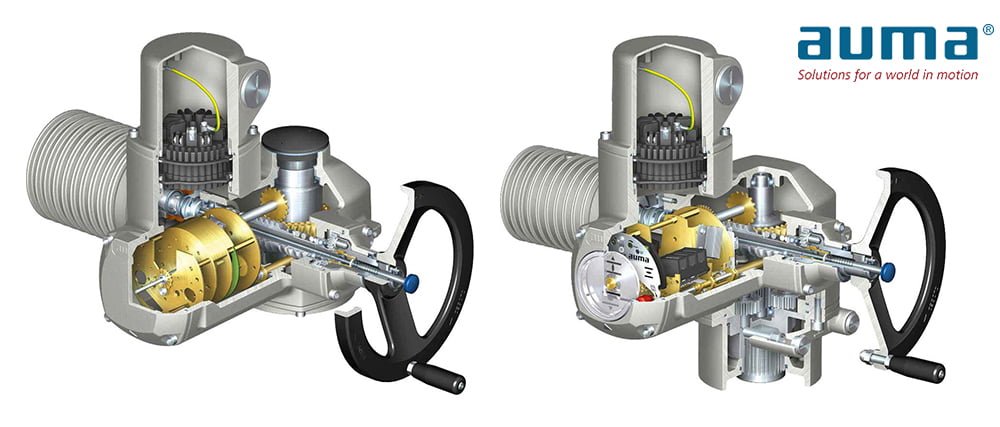

Valve actuators are devices that convert energy into valve motion, which can be used to control the flow of water in a water management system. They are used to open and close valves, adjust the flow rate, and regulate pressure. Actuators can be powered by different sources, including electricity, hydraulics, and pneumatics. The type of actuator used in a water management system will depend on the application, as well as the size and complexity of the system.

Electric valve actuators are powered by electricity and used in systems requiring precise control. They are easy to install and maintain and can be controlled remotely. Hydraulic actuators, on the other hand, are powered by hydraulic fluid and used in systems requiring high force and torque. They are more expensive than electric actuators but are more durable and can handle heavy loads. Pneumatic actuators are powered by compressed air and are used in systems requiring fast and precise control. They are less expensive than hydraulic actuators but more expensive than electric actuators.

Electric valve actuators used in water management systems

Electric actuators are the most commonly used types of actuators in water management systems. They have unique features, advantages, and disadvantages, making them suitable for different applications.

Devices such as AUMA valve actuators are powered by electricity and used in systems requiring precise control. They can be controlled remotely, and their operation can be automated, making them ideal for large and complex water management systems. They are also easy to install and maintain and have a long service life. Electric actuators come in different sizes and can handle different loads, making them suitable for a wide range of water management applications.

The specifications of actuators for a water management system depend on the application, as well as the size and complexity of the system.

Functions of valve actuators in water management

Valve actuators play a critical role in water/wastewater management systems by controlling the flow of water and ensuring that it is distributed efficiently. They are used to automate valves, adjust the flow rate, and regulate pressure, among other functions. The different functions of actuators in water management industry include flow control, valve automation, and pressure control.

Flow control

Flow control is the process of regulating the flow rate of water in a water management system. Actuators are used to adjust the flow rate of water by opening and closing valves. The flow rate can be adjusted to meet the system’s demands, ensuring that water is distributed efficiently.

Valve automation

Valve automation is the process of automating valves in a water management system. Actuators are used to open and close valves automatically, eliminating the need for manual operation. Valve automation improves the efficiency of the system and reduces the risk of human error.

Pressure control

Pressure control is the process of regulating water pressure in a water management system. Actuators are used to adjust water pressure by opening and closing valves. The pressure can be adjusted to meet the system’s demands, ensuring that water is distributed efficiently.

Valve actuators are essential components of both water management and wastewater treatment systems. They play a critical role in regulating water flow, valves, and pressure. The different functions of actuators in water management systems include flow control, valve automation, and pressure control, among others.

Choosing the right actuators for water management

Choosing the right actuator for your specific water management needs is essential to ensure optimal performance and efficiency of the system. There are several factors to consider when choosing the right actuators, including size, power source, and compatibility with existing systems.

Actuator size and capacity

Size is an essential factor to consider when choosing the right actuators for your specific water management needs. The size of the actuator will depend on the application, as well as the size and complexity of the system. Choosing an actuator that can handle the load and is compatible with the system is essential.

Power source

The power source is another essential factor to consider when choosing the right actuators for your specific water management needs, and it depends on the application and power availability. Electric valve actuators are the most commonly used type of actuator and are powered by electricity. For these actuators to work properly, an uninterrupted electricity supply with the required current strength is needed.

Compatibility with the water management system

Compatibility with existing systems is another essential factor to consider when choosing the right valve actuators for your specific water management needs. It is essential to choose an actuator that is compatible with existing systems to ensure optimal performance and efficiency of the system.

Choosing the right valve actuator for your specific water management / wastewater treatment needs is essential to ensure optimal performance and efficiency of the system. When choosing the right actuators, factors include size, power source, and compatibility with existing systems.

A case study of successful implementation of actuators in water management systems

Several case studies have been conducted to evaluate the effectiveness of actuators in water management systems. These case studies have shown that using valve actuators in water management systems can improve efficiency, reduce wastewater, and improve system reliability.

One case study conducted by the City of Los Angeles demonstrated the effectiveness of using electric actuators to control water flow in the city’s water distribution system. The study showed that using electric actuators improved efficiency, reduced water waste, and improved system reliability.

This case study clearly demonstrates the effectiveness of using actuators in water management systems to improve efficiency, reduce water waste, and improve system reliability.

Maintenance and troubleshooting tips for actuators in water management systems

Maintaining and troubleshooting actuators in water management systems is essential to ensure optimal performance and efficiency of the system. Regular / preventative maintenance and troubleshooting can help identify potential issues before they become significant problems.

Regular actuator maintenance in water management systems

Regular maintenance of actuators in water management systems includes cleaning and lubricating the actuator, checking the wiring and connections, and inspecting the actuator for signs of wear or damage. Troubleshooting potential issues with actuators include checking the power source, wiring and connections and inspecting the actuator for signs of wear or damage.

It is essential to follow the manufacturer’s recommendations for maintenance and troubleshooting to ensure optimal performance and efficiency of the system.

Future trends and advancements in the use of actuators for water management

The use of actuators in water management systems is expected to continue to grow in the future as the demand for clean water increases and the adoption of advanced technology becomes more prevalent. The future of actuators in water management systems is expected to include using advanced sensors and machine learning algorithms to optimize the system’s performance.

Advancements in the use of actuators for water management are also expected to include the development of more efficient and durable actuators, the integration of actuators with other advanced technologies, and using actuators in new and innovative applications.

The future of actuators in water management is bright, and the continued adoption of advanced technology is expected to drive further advancements in the use of actuators for water management.

Conclusion on actuators running in water management systems

Water management is a critical aspect of our daily lives, and the use of advanced technology, like actuators, has become necessary to ensure the sustainable use of our precious water resources. Actuators play a significant role in water management systems by controlling water flow and ensuring that it is distributed efficiently. The different types of actuators include electric, hydraulic, and pneumatic, and each type has its unique features, advantages, and disadvantages.

Actuators offer several benefits when used in water management systems, including improved efficiency, reduced wastewater, improved system reliability, and improved safety. When choosing the right actuator for your specific water management needs, it is essential to consider factors such as size, power source, and compatibility with existing systems.

The future of actuators in water management is expected to include advancements in technology, such as integrating sensors and machine learning algorithms, developing more efficient and durable actuators, and using actuators in new and innovative applications. By incorporating advanced technology, like actuators, in water management, we can ensure the sustainable use of our precious water resources for generations to come.