What are electric valve actuators?

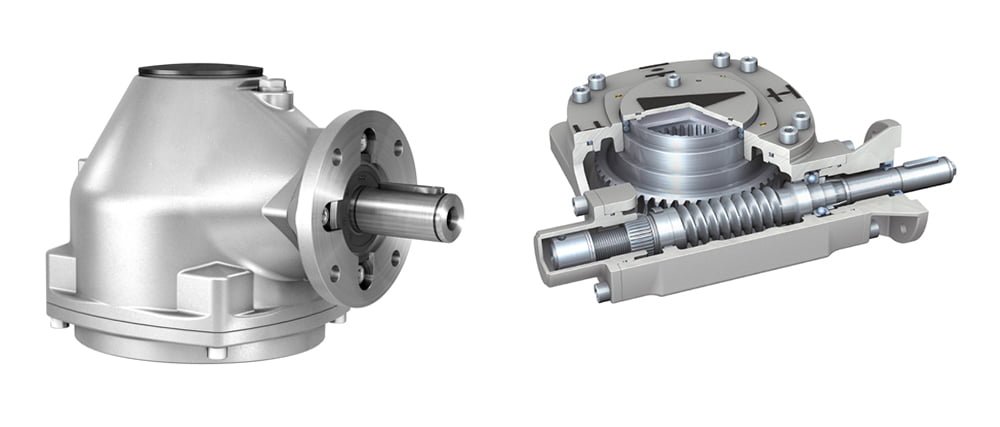

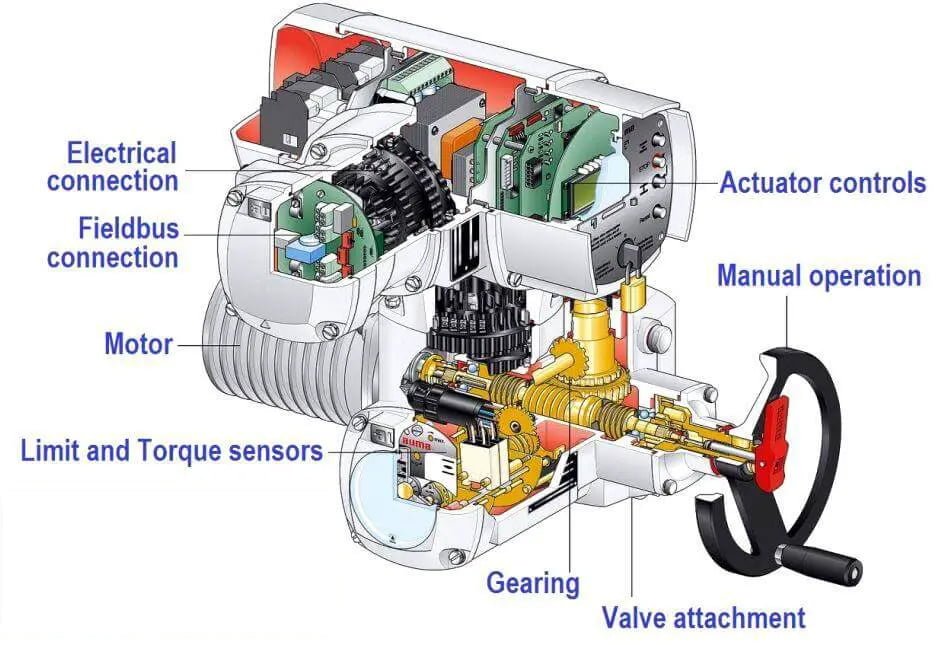

Electric valve actuators are devices that use electricity to control the opening and closing of valves in industrial processes. The electric valve actuator consists of an electric motor, gearbox, and control unit. The electric motor provides the power to operate the valve, and the gearbox converts the motor’s rotational motion into the linear motion required to operate the valve. The control unit is responsible for receiving signals from a controller and translating them into the appropriate action to operate the valve.

Electric valve actuators are used in a wide range of industries, including oil and gas, water treatment, HVAC, and more. They are also used in various applications, including pipeline control, flow control, pressure control, and temperature control.

Electric valve actuators have several advantages over traditional pneumatic or hydraulic actuators. They are more precise, provide higher efficiency, and require less maintenance. Electric valve actuators are also more environmentally friendly since they do not require the use of compressed air or hydraulic fluids.

How do electric valve actuator components work?

Electric valve actuators work by converting electrical energy into mechanical motion to operate a valve. The electric motor provides the rotational motion required to operate the valve, while the gearbox converts the rotational motion into the linear motion needed to open and close the valve.

The control unit is responsible for receiving signals from a controller and translating them into the appropriate action to operate the valve. The controller can be a manual switch, a computer program, or a remote control system. The controller sends a signal to the control unit, which activates the electric motor and operates the valve.

Electric valve actuators are capable of providing precise control over the opening and closing of valves. They can also operate valves much faster than traditional pneumatic or hydraulic actuators, providing greater efficiency in industrial processes.

Electric valve actuator components in industrial automation

Electric valve actuators provide several benefits to industrial automation processes. They offer precise control, higher efficiency, and improved safety.

One of the significant advantages of electric valve actuators is their ability to operate valves with high precision. They can provide accurate positioning and control over the valve’s opening and closing, resulting in better process control and higher product quality. Electric valve actuators also offer faster response times than traditional actuators, providing greater flexibility in industrial processes.

Electric valve actuators are also more energy-efficient than traditional pneumatic or hydraulic actuators. They consume less energy during operation, resulting in lower energy costs and a reduced carbon footprint. They also require less maintenance than traditional actuators, resulting in lower maintenance costs and improved reliability.

In terms of safety, electric valve actuators offer several advantages over traditional actuators. They are less prone to leaks and spills since they do not require the use of compressed air or hydraulic fluids. Electric valve actuators are also easier to control remotely, reducing the risk of operator injury in hazardous environments.

Types of electric valve actuators - rotary, linear, and quarter-turn

Electric valve actuators come in three main types – rotary, linear, and quarter-turn. Each type is designed for a specific type of valve and a specific industrial application.

Rotary electric valve actuators are used to operate ball valves, butterfly valves, and plug valves. These actuators provide a rotating motion required to operate the valve.

Linear electric valve actuators are used to operate gate valves, globe valves, and diaphragm valves. These actuators provide a linear motion required to operate the valve.

Quarter-turn electric valve actuators are used to operate valves that require a 90-degree rotation to open or close. These actuators are commonly used in ball valves, butterfly valves, and plug valves.

The type of electric valve actuator used in an industrial process depends on the type of valve being operated and the specific requirements of the application.

Applications of electric valve actuators in different industries - oil and gas, water treatment, HVAC, and more

Electric valve actuators are used in a wide range of industries, including oil and gas, water treatment, HVAC, and more. These actuators are used in various applications, including pipeline control, flow control, pressure control, and temperature control.

In the oil and gas industry, electric valve actuators are used to control the flow of crude oil and natural gas through pipelines. They are also used in the refining process to control the flow of different chemicals and products.

In the water treatment industry, electric valve actuators are used to control the flow of water through treatment plants. They are also used to control the flow of chemicals used in the treatment process.

In the HVAC industry, electric valve actuators are used to control the flow of air and water through heating and cooling systems. They are also used to control the flow of refrigerant through air conditioning systems.

Electric valve actuators are also used in the food and beverage industry, pharmaceutical industry, and manufacturing industry. They are used to control the flow of different products through manufacturing processes and to control the temperature and pressure in different applications.

Factors to consider when choosing electric valve actuators

When choosing electric valve actuators for industrial automation processes, several factors need to be considered. These factors include the type of valve being operated, the application requirements, and the environment in which the actuator will be used.

The type of valve being operated determines the type of electric valve actuator required. Different types of electric valve actuators are designed for different types of valves, as mentioned earlier. The application requirements, such as the flow rate, pressure, and temperature, also need to be considered when choosing electric valve actuators.

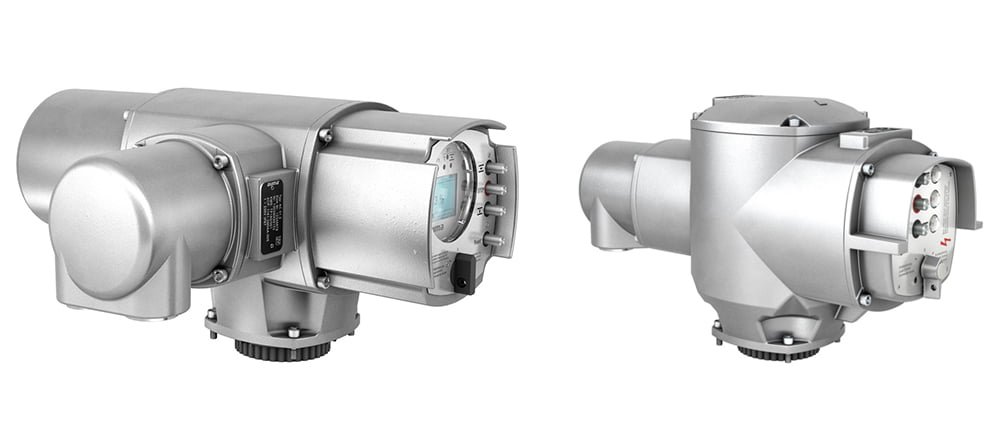

The environment in which the electric valve actuator will be used also needs to be considered. Factors such as temperature, humidity, and corrosive substances can affect the performance and lifespan of the actuator. In hazardous environments, explosion-proof electric valve actuators may be required.

Maintenance and troubleshooting tips for electric valve actuators

Proper maintenance of electric valve actuators is essential for their efficient and reliable operation. Regular maintenance includes cleaning and lubricating the actuator components, checking for signs of wear and tear, and testing the actuator’s performance.

When troubleshooting electric valve actuators, it is essential to identify the root cause of the problem. Common problems with electric valve actuators include motor failure, gearbox failure, and control unit failure. Once the problem has been identified, the appropriate repair or replacement can be carried out.

Future trends in electric valve actuator components and industrial automation

The electric valve actuator industry is constantly evolving, with new technologies and innovations being introduced regularly. The focus is on developing more energy-efficient and eco-friendly electric valve actuators that provide greater precision and flexibility in industrial processes.

One trend in electric valve actuator components is the use of smart technology and the Internet of Things (IoT). Smart electric valve actuators can be connected to a network, allowing for remote monitoring and control. This technology provides greater flexibility in industrial processes and can help reduce energy consumption and maintenance costs.

Another trend is the use of eco-friendly materials and manufacturing processes in electric valve actuator production. This approach helps reduce the carbon footprint of the industry and promotes sustainability.

Conclusion - Why electric valve actuator components are crucial in industrial automation

Electric valve actuators are a vital component of modern industrial automation, providing precise control, higher efficiency, and improved safety. They are used in various applications in different industries, including oil and gas, water treatment, HVAC, and more. When choosing electric valve actuators, several factors need to be considered, including the type of valve being operated, the application requirements, and the environment in which the actuator will be used. Proper maintenance and troubleshooting are essential for the efficient and reliable operation of electric valve actuators. The future of electric valve actuator components is focused on developing more energy-efficient and eco-friendly technologies that provide greater flexibility and precision in industrial processes.